PET strap is a type of strap made of polyethylene terephthalate (PET), a thermoplastic resin highly resistant to stretching and tearing. It is used in a variety of applications to tie, bundle and reinforce products.

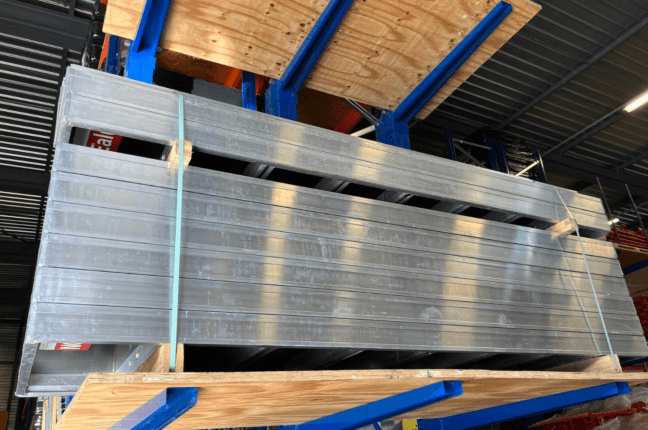

PET strap often used for industrial packaging to secure loads on pallets or to close package. It can also be used to attached smaller products, such as boxes or bags, to keep it together during transportation or storage.

The PET strap’s advantages are numerous. First, it is more resistant than traditional plastic straps such as polypropylene straps, which means it can support heavier loads without breaking.

It is also more resistant to weather and UV, making it ideal for outdoor use. In addition, PET strap is easy to recycle and revalue, making it a choice more respectful for the environment.

In other word,PET strap is a solid, reliable choice for packaging and bundling applications, thanks to its resistance to stretching, tearing and weathering, as well as its recyclability.

Due to these advantages, PET strap is widely used in logistics, distribution and transportation industries for voluminous and heavy loads strapping.

PET strap advantages

- Steel strap alternative

- High resistance to tearing and breaking. PET strap is stronger than other strap materials, such as PP (polypropylene), making it more durable and safer for transport and storage.

- Rot-proof and non-corrosive. PET strap resists humidity and temperature variations. It won’t rust or stain.

- Low elongation: PET strap has a low elongation capacity, making it rigid and more stable to maintain products and loads in place.

- Low elasticity: PET strap has a low elasticity capacity, which means it won’t deform or shrink when subjected to tension or pressure.

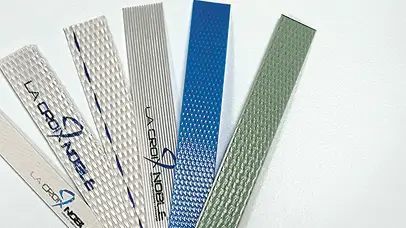

PET strap range

- From 9 to 32 mm

- From 0,5 to 1,27 mm of thickness

- Embossed or smooth PET

use with

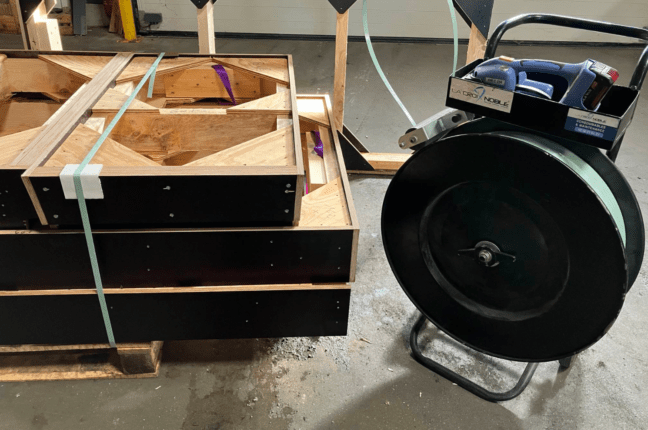

- Friction or automatic strapping machines

- Dispenser D50, D55, D1000, D200, or D872

- Strap pass Strapfix to limit MSD (Musculoskeletal disorders)

Services

Printed strap

Take advantage of a new communication medium with printed strapping.

Strap waste recycling

Recycle your strapping waste with our 3R program. A 100% La Croix Noble service.

Cut to size

We cut all types of straps, ties, strapping, and ropes to your desired length.

Métis® load security

A service to measure the load security of strapped goods.