An additional service (available in France only) to measure the safety of loading strapped goods.

What is strapping optimization?

It’s finding the right combination Straps & Strapping tools

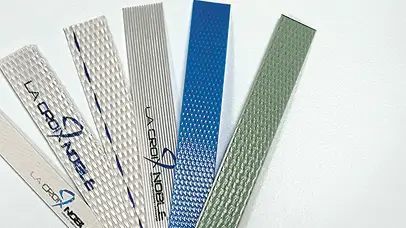

1/ Choose the right strap

It sounds simple, but it’s far from it – we’ve got the experts for that! How much does your load weigh? How many straps do you use? Which tools do you use for strapping? What are the storage conditions? Here’s everything you need to know to choose the right strap. We’ll work with you to select the strap that best matches all these parameters, the one that requires the least amount of raw materials, and therefore saves you money: both in purchasing and in CO2 (lower manufacturing costs).

100% CSR – QHSE approach

2/ Choose the right tool settings

There’s no need to tighten as much as possible! The best strapping is the one where we tighten just enough and respect the drying time.

TENSION test

MÉTIS test

STRAP + STRAPPING TOOL OPTIMIZATION PROPOSAL

CHECK THE RECOMMENDATIONS ON YOUR PREMISES

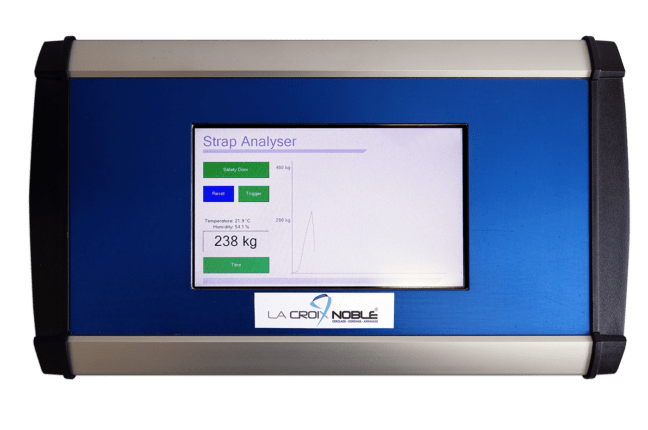

MÉTIS IS A TECHNICAL APPROACH TO MEASURING LOAD SAFETY LEVELS: we optimize the strap to your tensioning requirements.

90% of strap breakage occurs at the weld. That’s why we recommend the best settings to optimize: strap and strapping tools. The perfect combination for maximum savings.

Our 5-step optimization measurement service:

- Discover the Métis® project on your premises: we collect all the data and samples to measure your strapping and guarantee your satisfaction.

- We’ll draw up your specifications and send our lab all the data and samples to be studied and tested.

- Weld and strap testing with our Métis® device.

- Analysis and submission of our recommendations report.

- Validation of recommendations with a final on-site appointment to test our solutions.

ADvantages:

- There’s no need to start out with straps that are too heavy or strapping tool settings that are too high. Use less strap and consume less!

- Safety: know that you’re transporting your goods in complete safety, thanks to our advice.

- Sustainable: reduce your CO2 footprint by using application-specific strap.

- Recover raw materials: by reducing the amount of strap needed for your application, you can reduce the amount of material input and plastic waste created.

- Cut costs: reduce downtime by better understanding your process.

- Reduce the need for regular maintenance or breakage of your strapping tools by opting for the settings recommended by our experts. Less plastic waste in your tools = less clogging = longer tool life.

Services

Cut to size

We cut all types of straps, ties, strapping, and ropes to your desired length.

Maintenance

We perform maintenance and after-sales service

Printed strap

Take advantage of a new communication medium with printed strapping.

Métis® load security

A service to measure the load security of strapped goods.

Strap waste recycling

Recycle your strapping waste with our 3R program. A 100% La Croix Noble service.

Experts SINCE 1986

Customization

Solutions tailored to your needs – not the other way around.

Fast shipping

Immediate availability of your products.

Dedicated support

Responsive support at every stage.

Delivery tracking

Real-time delivery tracking for streamlined logistics.

After-sales service

Support over the phone, or by video – whatever suits you best.

Customer satisfaction

Your satisfaction comes first.

Customization Available

Solutions That Adapt to Your Needs

Dedicated Support

Responsive Support Every Step of the Way

Fast Shipping

Immediate Availability of Your Key Products

Customer Satisfaction

Your Satisfaction, Our Top Priority