Automated Packaging line

Our core business

for over 40 years

From the very beginning, our expertise has been built on the design and implementation of customized automated packaging lines. We also integrate stand-alone machines, perfectly aligned with our clients’ performance, productivity, profitability, and cost-control requirements.

We support you at every stage of your project: needs assessment, feasibility study, technical design, and the search for tailor-made solutions. Thanks to many years of close collaboration with leading equipment manufacturers, we have developed strong expertise that enables us to effectively address the vast majority of industrial challenges.

Our complete range of equipment is designed to precisely adapt to the constraints of every production environment: case erectors and sealers, palletizers, conveyors, as well as Spider robots from Montech – a brand we exclusively represent in France through La Croix Noble.

The stages of an automated packaging line

01.Case Erector

The case erector automatically unfolds your flat cartons and transforms them into ready-to-fill packages. Easy to use, it fits seamlessly at the start of your packaging line, helping to optimize your production flow.

02.bag insertion

Machines designed to automatically insert a bag inside the case or container. A sealing option is available depending on your protection or sealing requirements.

03. Automatic case packer

The case packer creates batches by precisely counting the items to be inserted into each carton. It handles picking, positioning, and automatic loading—your boxes are ready for shipment in no time.

04. Bag sealing

Once the case is filled, the machine automatically closes the inner bag. Optionally, a sealing system can be integrated to provide enhanced protection for your goods.

05. Case sealing

Once the case is filled, the machine automatically closes the inner bag. Optionally, a sealing system can be integrated to provide enhanced protection for your goods.

06. Spider palletizing system

Automatic palletizer available in column or gantry version, depending on your facility layout. The gantry model requires a high ceiling clearance, while the column palletizer is ideal for more space-constrained environments.

07. Top sheet placement

After palletizing, a top sheet is automatically placed over the load to complete the packaging process. This step prepares the pallet for stretch wrapping, ensuring optimal protection before shipping.

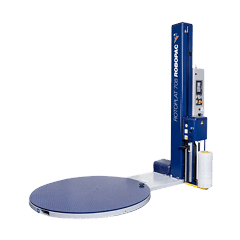

08. Stretch wrapper

Integrated at the end of the line, the stretch wrapper automatically wraps your pallets to ensure stability during transport. An efficient and reliable solution to secure every shipment.

09. Strapping machine

For certain loads, high-strength strapping is essential to ensure perfect stability during transport. At the end of the line, an automatic strapping machine applies vertical, horizontal, or orbital strapping based on your specific needs.

ProduCTS

Industries

Food and beverage industry

Our packaging lines meet the strict requirements of the food and beverage industry, ensuring hygiene, traceability, and high production throughput.

Chemical industry

Designed to meet the specific constraints of chemical products, our solutions ensure safety, dosing precision, and resistance to demanding industrial environments.

Cosmetics

We offer equipment tailored to the needs of the cosmetics industry, combining delicate handling, impeccable cleanliness, and flexibility for a wide range of formats.

Logistics

The packaging line plays a key role in logistics: it ensures the strapping of packages and pallets to maintain load stability and reduce the risk of shifting or damage.

Customization Available

Solutions That Adapt to Your Needs

Dedicated Support

Responsive Support Every Step of the Way

Fast Shipping

Immediate Availability of Your Key Products

Customer Satisfaction

Your Satisfaction, Our Top Priority